Powder Enamel Cabinets

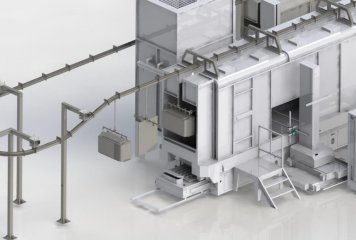

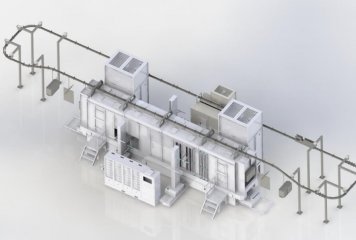

POWDER ENAMEL FACILITY

Powder enamel application is a coating method based on electrostatic foundation. By providing high pressure to the surface to be coated with enamel coating, the grounded material is subjected to coating process thanks to the electrostatic feature loaded during the spraying of powder paint particles.

In powder enamel application, there is a positive and negative pole formation along the electrostatic powder enamel line. The formation of reverse poles between the powder paint and the material surface creates an electrostatic field, causing the dust particles to move to the surface of the material. As a result of this shooting, paint is adhered to the material surface.

What are the Advantages of Powder Enamel Coating?

Electrostatic powder enamel oven, which is the most important element in the powder enamel coating process, improves the adhesion quality of the paint to the material surface by providing the coating material to cook. The most meticulous workmanship is revealed at every point along the electrostatic powder enamel line, which is used to create a perfect coating surface. The most important role in the best quality coating of recessed surfaces is that the spray guns direct powder particles to the right area with high pressure.

Powder enamel coating process is one of its most important features that it provides economic advantage. After the powder paint particles thrown on the surfaces are collected in a pool as a result of not sticking to the surfaces, the same powders offer the opportunity to be used again.

During the entire powder enamel coating process, the air used, including the electrostatic powder enamel oven, is filtered and made ready for use again by cleaning. The furnace, gun and compressed air cabin used during powder enamel coating offer the opportunity to clean easily with compressed air.

What are the Uses of Powder Enamel?

The frit used in enamel coating processes is generally applied on steel and cast iron products. Electrostatic powder enamel furnace is used in order to obtain solid and high quality surfaces in powder enamel coating processes in this area.

As usage areas;

Some of these are household appliances made from steel products, oven, stove, pot, washing machine, dishwasher, tumble dryer, extractor, gas water heater.

Among the sanitary ware products made of steel, the most frequently used materials such as bath tub, shower cabin pool, sink, gas stove.

It is observed that the coating processes made by using enamel furnaces in the industrial sector and construction sector are subjected to powder enamel coating process to increase the strength of the outer surfaces of the barriers celebrated in the chemical industrial processes, boilers used in the traffic lines, stair handrails equipped in the subway lines and the controlled entrance and exit areas. .