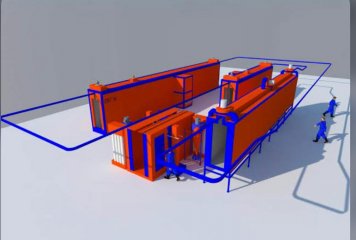

Powder Coating Booths and Baking Ovens

Electrostatic Powder Coating Plant

Powder coating is a completely dry coating system. It consists of electrically charged ground resin, pigment and other raw material particles and is sprayed on the objects to be painted.

The materials to be painted are grounded, so that the loaded particles melt in the curing furnaces and adhere to each other before they form a smooth, durable and quality coating. Powder paints are divided into thermos meat (heat curing) and thermo plastic. Heat curing powder paints are the most commonly used powder paints. During the curing process, they undergo an irreversible chemical change and when they are heated again they do not melt and become liquid. Thermoplastic powder paints, on the other hand, can be melted over and over again and become solid when cooled. They are especially suitable for applications made at high film thicknesses with the most demanding performance requirements.

WHAT IS ELECTROSTATIC POWDER PAINTING

Electrostatic powder coating is a solvent-free surface coating method. The coating material is very fine powder paint particles that make up the top layer of paint.

Powder paint is thrown in the paint booth through special paint guns. While passing through the gun, powder paint particles charged electrostatically adhere to the material to be painted in the cabin and coating process is realized. In order for the powder paint to fully adhere to the surface of the material, the material must also be grounded very well. Excessive paint is collected and put back into use thanks to the paint recovery system in the cabin. Paint recovery system is one of the biggest economic advantages of electrostatic powder coating technology. After the material is covered with powder paint, it enters the baking oven. The oven temperature of 200ºC allows the powder paint to melt and adhere to the material. The result is a very durable, economical, environmentally friendly, wide color gamut and a glossy surface finish.

Its solvent-free, surface quality, durability, paint recovery system, economy and environmental sensitivity make electrostatic powder coating a more attractive alternative to traditional painting processes.

Application of Powder Paint

Powder coating application consists of three main steps.

Cleaning and pretreatment

Powder coating application

Baking

Cleaning and pretreatment

In order to get perfect results from the painting process, the part to be painted must be cleaned and pre-treated. There are various methods used in part cleaning. Acidic cleaners work well for inorganic contaminants, while alkaline cleaners are more suitable for organic contaminants. Degreasing chemicals are used for other organic impurities.

Phosphating is usually required after this cleaning process. However, for aluminum profiles used for architectural applications, passing through chromic acid solution gives better results.

Paint Application

Powder coating is carried out by means of an electrostatic gun. For this purpose, there are two types of pistols, corona and tribo. In the Corona type gun, the powder is electrostatically negatively charged when leaving the gun, thanks to a high-voltage electrode located at the tip of the gun. Since the part to be painted is grounded, the electrostatically charged paint easily adheres to the part. However, sometimes a very indented and protruding parts may have a Faraday effect and the entrance of dust into the pit areas may be problematic. In these cases, tribo type guns are used. In this type of gun, the paint is loaded with positive friction only without applying high voltage.

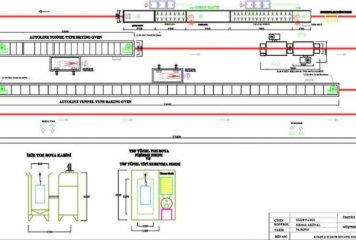

Baking

Powder coating is put into baking. At this stage, the part is exposed to the time and temperature given in the properties of the paint. The paint melts at this temperature and cures after forming a flat surface. At the end of this period, after the part is removed from the oven, the painting process is completed. Powder Coating products usually cure at 200 degrees in 10 minutes. However, the 10-minute time mentioned here is started after the piece reaches 200 degrees.

Process Efficiency of Powder Coating Technique

The material usage efficiency in powder coating approaches to 100%. Extra sprayed powder particles are recycled and returned to the painting system for reuse. As a result, powder coating requires 1/2 to 1/3 less material than wet paint.

Powder Coating Makes Automation Easy

Three important factors of powder coating offer solutions suitable for automatic application:

- Electrostatic method; creates a wrapping effect and the powder is homogeneously coated on the product.

-Easy to reach corners and recesses with powder paint.

-Dust does not drip paint, which simplifies the placement of the gun.

Superiority of Powder Coating

The "Thixotropic" properties of the powder coating film ensure that the coating as a result of cooking is equal to that obtained by the dry paint film. In the cooking process, polymerization of powder paint occurs and allows the paint film to spread and harden on the product. As a result, on the obtained coating; Significant improvements have been made in the field of excellent resistance to abrasion, rust, chemical attacks and external damages in general, and to facilitate application.

Environmental Protection

Electrostatic powder painting is a method that does not harm the environment; There are no organic substances in the powder paint that can evaporate. This means not only environmental protection, but also a potential savings in waste issues, chimney and duct cleaning, storage and occupational health compared to equivalent solvent-based painting systems for the manufacturer.

Business Economics

Electrostatic powder coating systems provide a significant operating economy.

Over-sprayed powder paint is reused with recovery.

There is no need for primer painting.

It is used as purchased from the powder coating manufacturer and does not require solvent mixing or similar processes before use.

Filtered or filtered air is sufficient.

Advantages of electrostatic powder paint

Electrostatic powder coating; provides long lasting, economical, perfect surface coating, ease of cleaning, environmentally friendly, easy maintenance, a wide variety of color options and aesthetic and easy to use products.

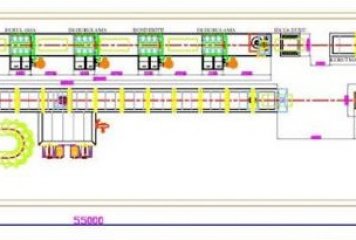

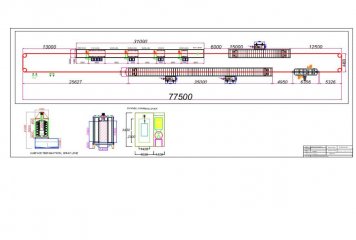

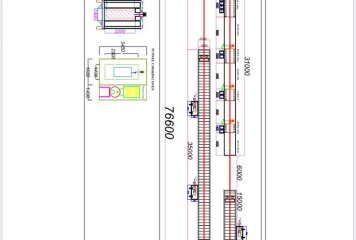

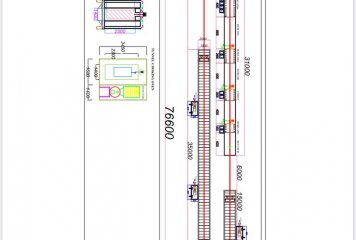

SPRAY LINE

The purpose of Spray Washing Lines is to ensure a good adhesion by cleaning the materials to be painted from all kinds of external factors by performing successful painting processes. This process ensures that the painted materials are resistant to oxidation against ambient conditions.

Spray or dip type systems are applied based on the size, properties and capacities of the materials to be painted.

The system that allows the surface to be cleaned to be burned with high-pressure and high-speed sprayed water or chemicals, without the need of a human factor, is called a spray washing line.

The purpose of installing the spray washing line is to clean the oil layer on the metal surface and create a thin film on the metal surface. After this process, the surface or metal to be painted is made more suitable for paint, more durable and protected against external factors. Thanks to this automatic system, chemical values and temperature values can be monitored and controlled continuously by digital indicators. Due to its operating mechanism, it is more efficient than dipping type surface cleaning and processing plants. Although the cost of acquisition is high, it pays for itself in a short time, and it provides an advantage to its user due to its low quality and consumption. In a working environment where the temperature is 45-55 ºC, the pressure is 1.5-1.8 bar and the time is minimum 1.5 minutes, the desired efficiency can be obtained under suitable conditions. Phosphated parts become ready to be painted after passivation and maximum 130ºC drying. Options for bathing parts and cleaning methods may differ depending on the potential of the workplace and its preference in the field of work. Thanks to this system, preparations are made before powder coating.

Spray washing line systems can vary from industry to industry in accordance with the needs and needs of the business.